A team of scientists grew polymer brushes on a silicon wafer and graphene oxide sheet, placing crystals on the surface that caused the growth of filaments. As a result, it was possible to control the density, length and chemical properties of micellar brushes, and using nanoparticles, scientists have shown the applicability of nanostructures for catalysis and the creation of antibacterial coatings.

In many areas (for example, lithography, the study of superhydrophobicity and cell adhesion), it is necessary to create nanostructures with precisely specified chemical and physical properties on the surface of materials. Hard surfaces can be modified by growing elongated polymer crystals on them, which are attached to them and together form polymer brushes. Synthesizing similar structures with precise characteristics on a larger scale, however, can be quite difficult.

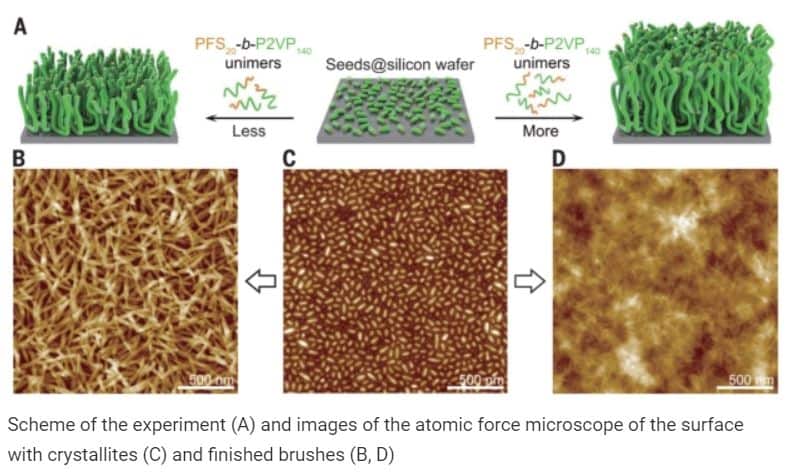

Jiandong Cai and colleagues from ShanghaiTech University synthesized a nanostructure from copolymer filaments on a solid silicon surface. Polymer filaments were grown on a silicon wafer with silanol groups, which formed hydrogen bonds with molecules of cylindrical crystallites capable of growing “hairs” from block copolymers in solution on both sides.

Using an atomic force microscope, the authors of the work were convinced that the crystallites were distributed uniformly over the surface. Then the silicon wafer was placed in a solution of polydimethylsiloxane, which began to crystallize, forming a layer of nanoscopic brushes. From the images of the atomic force microscope, the authors determined that the length of the polymer columns is about a millimetre, and in diameter, they were about 20 nanometers. Control experiments confirmed that the brushes were formed due to the presence of crystallites on the silicon wafer: without them, the polymer formed cylindrical micelles in solution and hardly attached to the wafer.

By adjusting the density of the brushes depending on the concentration of crystallites on the plate, the authors were able to synthesize surfaces with different hydrophobicity – with a contact angle of 81 to 109 degrees. By adding trifluoroacetic acid, the researchers achieved protonation and the formation of a positive charge on the brush, because of which it became hydrophilic (a wetting angle of 26 degrees). The new material was also able to be modified with gold or silver nanoparticles, due to which it began to possess catalytic and antibacterial properties, respectively.

Scientists also managed to grow brushes on the surface of the graphene oxide sheet: they remained stable for several months, and the crystallites formed hydrogen bonds with carboxyl and hydroxyl groups on the sheet.

Thus, the authors were able to demonstrate the applicability of the obtained structure as an antibacterial membrane and catalyst. According to scientists, the presented method of surface modification also allows you to finely control some of its chemical and physical properties, which can be useful in many areas.